Do you have any questions?

Overview

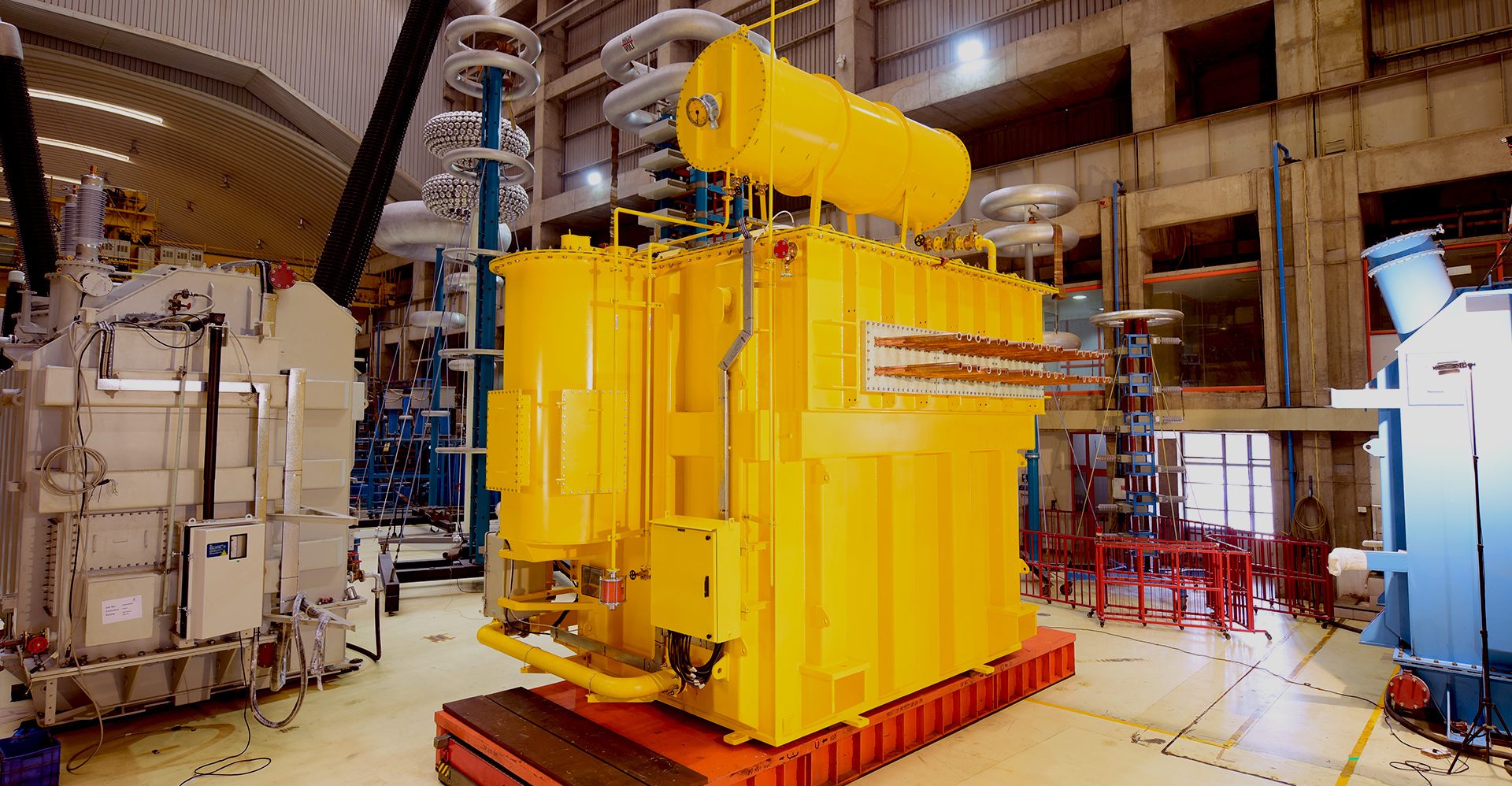

Furnace transformers are used to feed electric furnace used to melt and refine materials. Furnace transformers are associated with very high secondary currents and wide output voltage regulation in order to cope with the furnace needs. TARIL is well prepared and backed up with its manufacturing capacity and state of the art to cater to 300 million tons steel production (from present 126 million tons capacity) as planned by India till 2030 and also keep on supporting international requirement additionally.

Furnace transformers are key element of any steel plant; explicit engineering solutions are embraced in TARIL Furnace transformers in order to guarantee over time the best performances under the dielectric, thermal and mechanical stresses involved with such transformers in service life.

Furnace transformers are often associated with series reactor to control current thereby to stabilize the arc during fusion in order to improve the performance of the furnace.TARIL offers inbuilt series reactor along with furnace transformer depending on client needs.

Depending upon the client need TARIL offers:

- Single phase or three phase solution

- Inbuilt or separate auto transformer for regulation.

- Inbuilt Snubber circuit to overcome transient over voltages

- LV delta closure inside or outside the tank

- Single core or booster type solution

- LV terminals with or without water cooling, mounting on side or top of the tank.

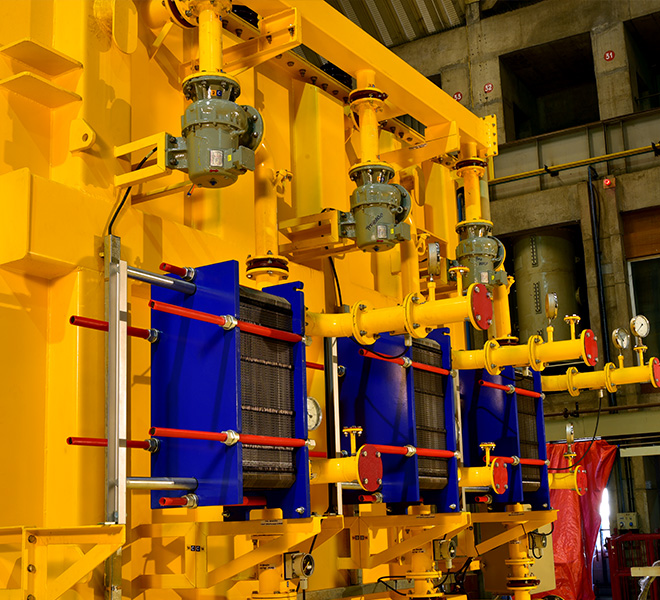

- Tube or plate type oil to water heat exchanger.

- Single phase or three phase solution

- Inbuilt or separate auto transformer for regulation.

- Inbuilt Snubber circuit to overcome transient over voltages

- LV delta closure inside or outside the tank

- Single core or booster type solution

- LV terminals with or without water cooling, mounting on side or top of the tank

- Tube or plate type oil to water heat exchanger

Sustainability goals

We offer the most complete industrial solutions in the century for the research, design & development of materials.

Guaranteed quality

The procedures and techniques that are used during the building process

Product Range Types

TARIL Furnace transformer product range covers 200 MVA and 120 kA, various types include:

- Electric Arc Furnace Transformer (EAF)

- Submerged Arc Furnace Transformer (SAF)

- Ladle Refining Furnace Transformer (LRF)

- DC Arc Furnace Transformer

- Induction Furnace Transformer

Auto transformers offers economical optimized solution for interconnection in grids while compared to conventional two winding power transformers. TARIL offers wide range of Auto transformers including constant or variable flux regulation, with or without tertiary winding in both single phase and three phase combinations upto 500 MVA and 1200 kV class.

The generator step-up unit transformers have delta-connected LV windings energized by the generator voltage and star connected HV winding connected to the transmission grid. TARIL offers wide range of generator step up unit transformers suitable for thermal, hydro and nuclear plant applications upto 1000 MVA, 765 kV class.

Small and medium power transformers are used mainly to evacuate solar and wind power generated to the main grid as well as catering plant loads. TARIL offers wide range of small to medium power transformers with tailor made requirements upto 150 MVA and 400 kV class.

The trackside traction transformers are used for stepping down the grid voltage levels for the railway network. Track side transformers undergoes severe duty conditions include overloading and frequent short circuit during service life. TARIL offers wide range of trackside traction transformers suiting railway requirements upto 50 MVA, 220 kV class.

TARIL Advantage:

Dynamic Short circuit tested designs

Attractive delivery

Excellent service record

Unit and station auxiliary transformers are used in thermal stations for feeding auxiliary power to various equipment’s. TARIL offers wide range of unit and station auxiliary transformers upto 125 MVA.

TARIL Advantage:

Dynamic Short circuit tested designs

Attractive delivery

Excellent service record