Do you have any questions?

Overview

The rectifier transformer is acting as link between the grid and the AC to DC converters. Application of rectifier transformer is to provide required number of phases, voltage shifts needed to realize the conversion and to adjust the rectifier input to vary the DC output voltage. Rectifier transformer is generally used in various applications such as electrolysis process, aluminum smelting, graphitizing etc.

Rectifier transformers are associated with very high secondary currents encompassed with huge harmonic content caused by semiconductors devices connected to transformer.

Depending upon client need TARIL offers,

Sustainability goals

We offer the most complete industrial solutions in the century for the research, design & development of materials.

Guaranteed quality

The procedures and techniques that are used during the building process

Product Range

TARIL Rectifier transformer product range covers 160 kA, various types include:

Applications of BCTs – The internally & externally mounted BCT is designed to be mounted onto a high voltage bushing shank along the ground collar, inside the tank of a power transformer, power circuit breaker or voltage regulator, that uses oil as the insulating medium. When properly installed, the Oil-type BCT can be used on higher system voltage levels while maintaining its own mere 600 Volt class rating. Its simple construction provides a low leakage product with extremely high short circuit capabilities.

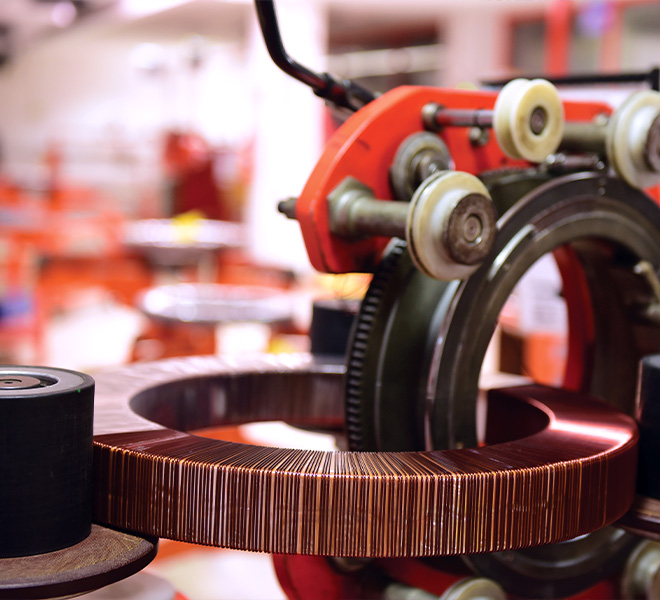

The Construction – The toroidal core is continuously tape-wound using cold rolled grain oriented electrical grade silicon steel, which receives a full stress relief anneal after it is wound to its specified dimensions. The secondary winding is then wound of enamel insulated copper wire over the cellulose insulated core with the turns equally spaced around the core periphery. When taps are pulled, they are wound in a manner that assures a fully distributed winding between any connections. The coil is then finished with a cotton wove fabric. All materials used have a minimum rating of 105°C and are compatible for use in hot transformer oil.

Size Selection – There are no “standard ratings” for BCTs. Each unit is customized design as per application. In addition to the current ratio, accuracy class and power frequency, some information regarding the equipment must be provided. To determine the physical size the limiting dimensions must be given, which are the minimum ID, the maximum OD and the maximum stack height. When stacking multiple OBCTs on the same bushing, the CT configuration must be given. To properly determine the Rating Factor, the maximum current rating of the bushing should be stated. To assure the BCT is properly sized for short circuit conditions, the maximum let-through current must also be provided. Finally, the lead wire gauge and length must be specified.

PRODUCT RANGE

T&R make Bushing CTs are designed and crafted according to customer specification as per global standards with:- Different accuracy classes (metering, protection, special protection and others)

- Available in a variety of winding arrangement, Single Ratio (SR), Dual Ratio (DR) or Multi Ratio.

- Additional options: primary current upto 6300 Amps, higher temperature class rating of 155°C.

Instrument transformers are hermetically sealed type in construction. The whole transformer assembly goes through vacuum drying in Vacuum Drying Chambers for 48hrs – 96hrs as per the rating in various stages. Under Vacuum the transformers are filled with filtered, de-aerated EHV grade transformer oil under vacuum and allowed for oil soaking for 12hrs-24hrs under pressure and at the end, the top chambers are sealed and further processed for several tests as per IEC / IS.

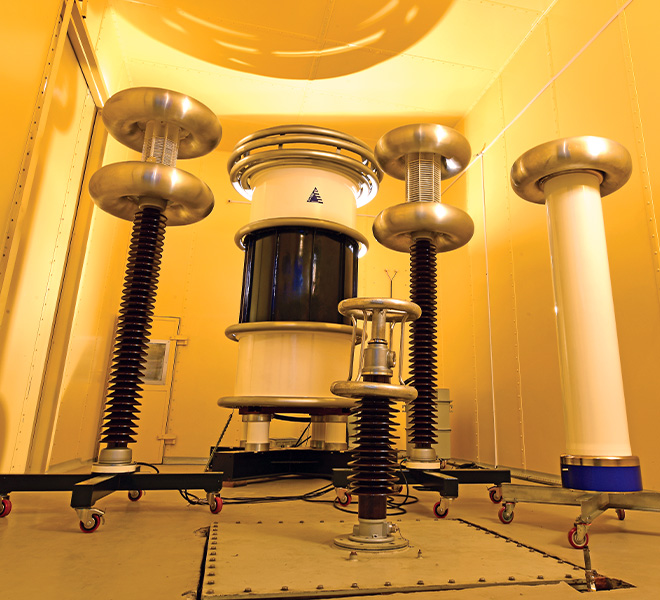

Each Current Transformer unit is strictly routine tested in an isolated shield HV AC Series Resonant System with specially made cage room for Partial Discharge and Capacitance & Tanδ to assure its quality and technical specifications.

Outdoor Oil Cooled Current Transformers (CTs) of 72.5 kV, 145 kV, 245 kV voltage class.

Type: Dead Tank

Burden: upto 50 VA

Accuracy Class: Metering, Protection, Special Protection

BIL (r.m.s. / kV peak): 140 kV / 350 kVp; 275 kV / 650 kVp; 460 kV / 1050 kVp Frequency: 50 Hz / 60 Hz

Applicable Standards: IS 2705, IS 16227 / IEC 61869, IEC 60044